3D Printing

For rapid prototyping of small components and scaled models, three 3D printers are available for use within the Fabrication Workshop.

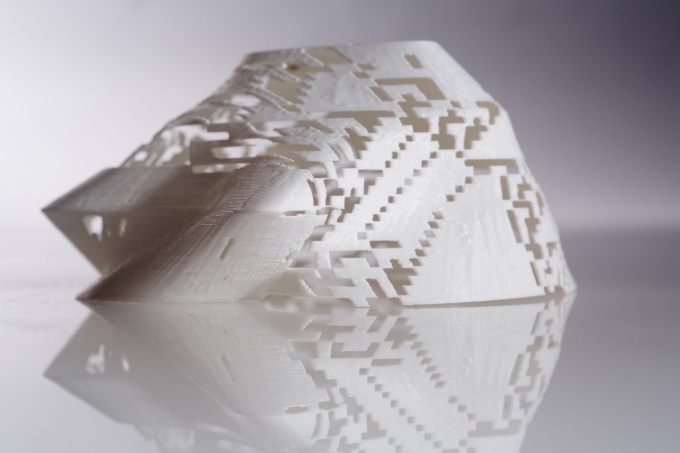

One Stratasys Dimension SST1200es uses FDM (fused deposition modeling) technology to build models using layers of ABS plastic and a soluble support material. In using a soluble support material, the printer can accurately and effectively print overhangs and voids with minimal manual post-processing on parts. The build bed for this printer is 10”W x 10”L x 12”H.

Recently, two FormLabs Form 2 SLA (stereolithography) printers have been added to the Fabrication Workshop. Although these machines have a smaller build bed at approximately 5.9”W x 5.9”L x 6.2”H, they are able to obtain a resolution of 0.025mm, creating more refined and dimensionally accurate parts. Supports are built from the same material as the model and removed prior to curing parts into a hard, plastic-like material.