Snap Interlock Module System

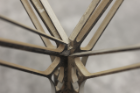

The SIMS steel module is the center of a new steel structural and facade assembly system designed by Jin Young Song in collaboration with the school's fabrication team and UB engineering faculty. Photo by Jin Young Song

Snap Interlock Module System (SIMS), developed by UB associate professor of architecture Jin Young Song, imagines a new system for building with steel in the 21st century construction industry. The prototype is the winner of the 2019 Forge Prize.

SIMS was designed in response to a changing paradigm in the urban environment. According to Song, the culture of public life in the city will increasingly demand a more flexible and deployable construction system.

Current conventions in construction are largely labor intensive and inefficient. Consider masonry stacking systems, such as brick-laying or reinforced concrete, which require skilled labor (even with the introduction of bricklaying robots) and are sensitive to environmental conditions such as temperature and moisture. At the same time, steel systems have not progressed beyond the post and beam system, which relies on the highly skilled welding and bolting of the joint. SIMS builds on the strengths and weaknesses of these systems as a stackable, part-to-whole system of interlocking steel modules.

SIMS is being developed with support from UB's Sustainable Manufacturing and Advanced Robotic Technologies Community of Excellence and in collaboration with several faculty from UB's Department of Civil Engineering.

History as inspiration: Stacking and the 'universal joint'

‘Stacking’ is the simplest and oldest building method employed, from the Great Wall of China, to the Hagia Sophia, to the Taj Mahal. Children’s toy blocks also present the fundamental human actions of ‘stacking’ within a part-to-whole system. Mortar and blocks form the basis of the masonry structure using bricks, stones, concrete blocks, and tiles as units. SIMS incorporates these ancient methods while proposing a novel framing system of stackable, lockable steel modules.

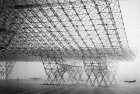

The system also draws inspiration from the German engineer Konrad Wachsmann who, in 1953, imagined a single universal structural element which, industrially produced, could be applied widely in building construction. Current smart fabrication techniques with advanced digital design tools allow architects to revisit Wachsmann’s holistic approach for a unit-based ‘part-to-whole’ system.

How it works: Fabrication and assembly

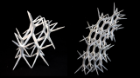

Design flexibility and construction efficiency is achieved through the design of the individual element, which features two sets of legs each extending outward from a center node. The first step is involves the creation of a single module through a bearing, or perpendicular, connection of two elements. Then, through a snapping connection, the four legs connect to four separate modules, from both the top and underside of the central module.

The configuration can be expanded or repeated to construct a larger structure, thereby eliminating the need for bolting or welding. Tests demonstrate that the interlocking motion falls into the elastic range of the material property and confirms that structural integrity can be maintained at the building scale.

A key collaborator with Song on SIMS' fabrication and assembly is Daniel Vrana, fabrication manager for the School of Architecture and Planning. The team has achieved mass production scalability and cost efficiency through a range of techniques, including CNC milling and multi-axis waterjet cutting. As a next step in this line of inquiry, the team is exploring CAMel, a plugin for Grasshopper (authored by Edmund Harriss of the University of Arkansas in conjunction with workflow design by UB and OMAX Corporation), which will introduce geometric dynamism through new edge conditions.

Along with increased geometric freedom, metal 3D printing generates the opportunity to explore new aspects of the system such as strength, monolithic construction, material composition and behavior, customizability, mass production and post-processing techniques. Such methods are under exploration with Buffalo Manufacturing Works.

Application: a building system for a DIY world

Song and his team envision a scenario where a single box of SIMS modules can be delivered to a customer, who can easily stack and assemble to build a single-story pavilion with a strength of steel construction without the need for fasteners or bonding. Two arched prototypes have been built using 3D printed building-blocks that test geometric flexibility. The parts are packed in one suitcase, delivered to site, and snap-aggregated into a small pavilion in less than two hours. Tests with steel units maintain this facility in assembly.

Potential applications include rapid construction of a steel barrier wall. Deployable walls and canopies can be built and disassembled. The wall can be used as sub-structure for building facade, rain screen, and solar panels. Vertical farming can be built using the modular configuration of the system.

Lead Architect

Fabrication Manager

Daniel Vrana (UB Architecture)

Structure Analysis

Xiandong He (PhD student, UB Department of Civil, Structural and Environmental Engineering)

Jongmin Shim (UB Department of Civil, Structural and Environmental Engineering)

Structure Analysis

Bonghwan Kim (Skidmore, Owings & Merrill LLP)

Student Researcher

Michael Gac (MArch)

Anita Lin (BS Arch)